Living aboard quickly taught me how to participate in, and rely on, a community. I couldn't have gotten my old water heater out of its nook behind the engine if a friend hadn't offered to cut it apart with a Sawzall while it was still in the boat.

It took an entire afternoon and evening, a rented Sawzall, and several beers but they got it out!

I used HDPE for a mount for the new water heater. The only heater I could find that would fit through the access hatch was quite a bit smaller than the old one.

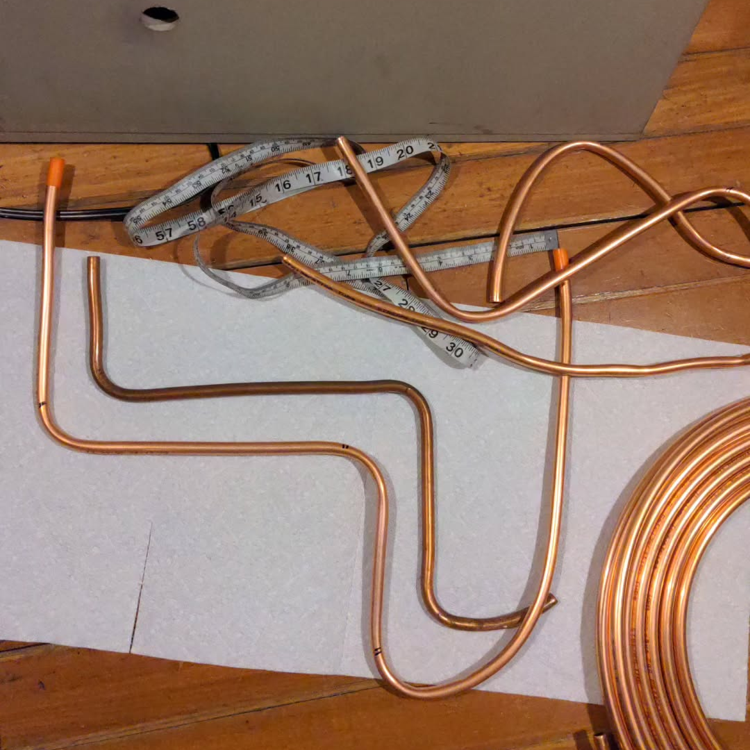

I couldn't use my diesel cabin heater until I replaced the old copper pipe and brass fittings. I filled the new pipe with sand to prevent it from collapsing when I bent it. It took a few tries but I finally got it.

Many of the windows leaked. Resealing them turned out to be one of the longest ongoing projects on the boat due to old sealant causing the gelcoat underneath to fail, broken aluminum frames that had to welded together or replaced, and half-done attempts by previous owners. A few friends helped over the course a month to scrape and sand.

The old fresh water pump contained materials not safe for potable water, the diaphragm in the accumulator tank (not pictured) was disintegrating, and all the old hoses were brittle and gross. I replaced the entire fresh water system, except for the tanks, which I treated with sanitizer.

Most people don't have to remove their kitchen sink and cabinetry to work on their home's diesel tractor engine.

The intentional holes in the hull, through-hulls, are a common cause of sinking when they fail. A friend helped me cut out the old ones (inset) with a holesaw. I glassed in new G10 backing plates to replace the wood ones and installed the new through-hulls with 3M sealant.